| Name | Test Force | Note |

| Micro hardness tester | ≤2kgf (19.6N) | In market, test force from 10g to 1kgf is most widely used |

| Macro Vickers hardness tester | >2kgf (19.6N) | In market, load 5kgf, 10kgf, 30kgf, 50kgf, 100kgf type Macro Vickers most widely used |

| Name | Load type |

| Micro hardness tester | Dead weights is widely used |

| Macro Vickers hardness tester | Closed loop load cell is widely used |

| Average Diameter of Indentation d | Min. Thickness of Specimen | |||

| Ball Diameter | ||||

| D=1 | D=2.5 | D=5 | D=10 | |

| 0.2 | 0.08 | | | |

| 0.3 | 0.18 | | | |

| 0.4 | 0.33 | | | |

| 0.5 | 0.54 | | | |

| 0.6 | 0.8 | 0.29 | | |

| 0.7 | | 0.4 | | |

| 0.8 | | 0.53 | | |

| 0.9 | | 0.67 | | |

| 1 | | 0.83 | | |

| 1.1 | | 1.02 | | |

| 1.2 | | 1.23 | 0.58 | |

| 1.3 | | 1.46 | 0.69 | |

| 1.4 | | 1.72 | 0.8 | |

| 1.5 | | 2 | 0.92 | |

| 1.6 | | | 1.05 | |

| 1.7 | | | 1.19 | |

| 1.8 | | | 1.34 | |

| 1.9 | | | 1.5 | |

| 2 | | | 1.67 | |

| 2.2 | | | 2.04 | |

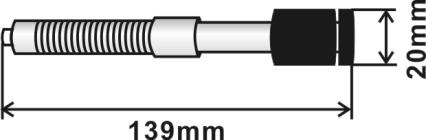

| Probe (Impact Device) | size | Photo |

| C | 139*20mm |  |

| D | 148*20mm |  |

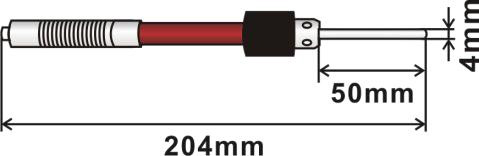

| DL | 204*50*4mm |  |

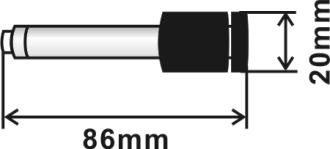

| DC | 86*20mm |  |

| D+15 | 164*14mm |  |

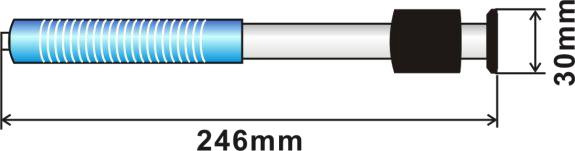

| G | 246*30mm |  |