- HOME

- PRODUCT

- HARDNESS TESTER

- CASES

- DOWNLOAD

- VIDEOS

- NEWS

- ABOUT US

- CONTACT

| Availability: | |

|---|---|

UTM-1EWS

EBP INSTRUMENTS

Shanghai

90 sets / month

TT in advance

1 set

Safety Device

1. Stroke protection: Machinery, computer double protection, prevent over preset

2. Force protection: system setting

3. Emergency stop device: handing emergencies

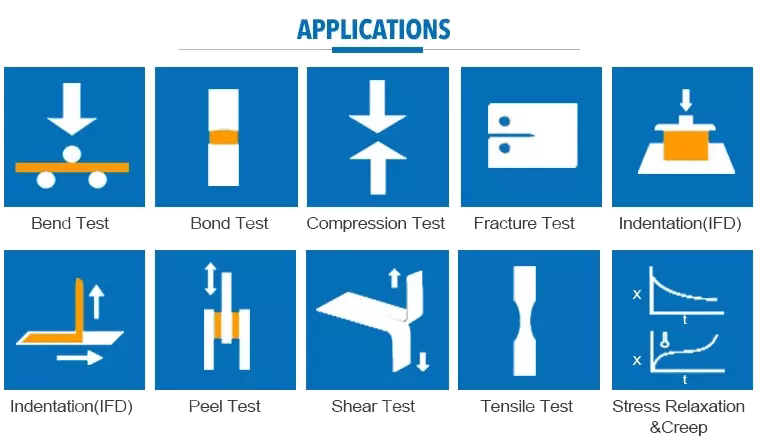

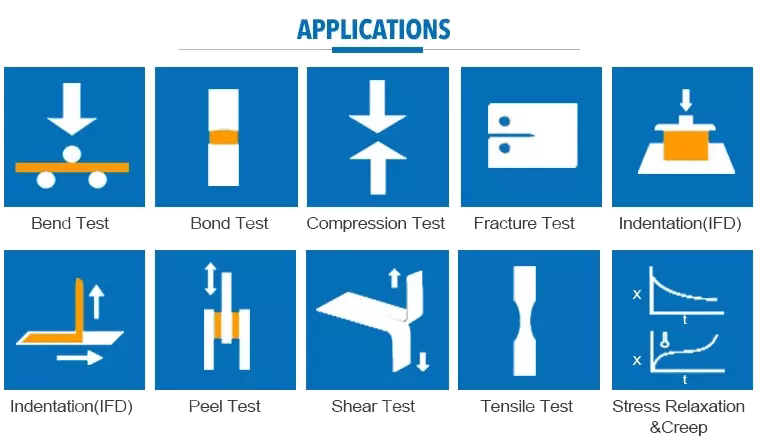

Application

It is applicable for wide range of material for tension, compression, bending, shearing and low cycle test. Suitable for metal, rubber, plastic, spring, textile, and components testing. It is widely used in the corresponding industries, research and development, test institutes and training centers etc.

Standards

ASTMA370,ASTME4,ASTME8,ASTME9,ISO6892,ISO7438,ISO7500-1,EN10002-4,GB/T228-2002, GB 16491-2008, HGT 3844-2008 QBT 11130-1991, GB13-22-1991, HGT 3849-2008,GB6349-1986, GB/T 1040.2-2006, ASTM C165, EN826, EN1606, EN1607, EN12430 etc.

Specification:

Model | UTM-0.1EWS, 0.2EWS, 0.3EWS, 0.5EWS, 1EWS,2EWS, 3EWS, 5EWS |

Structure | Single column double spaces |

Max. Load(kN) | 0.1 / 0.2 / 0.3 / 0.5 / 1 / 2 / 3 / 5 |

Material | All aluminum alloy surface spray painting shell |

Load accuracy | ISO 7500Class1/ Class0.5 |

Load range | 2%~100%F·S/ 0.2%~100%F·S |

Load resolution | 1/ 300000 |

Resolution of displacement | 0.01mm |

Test speed(mm/min) | 0.05-500 stepless arbitrary setting |

Speed accuracy | within ±1% set speed |

E-Tensile space(mm) | 600 (can be customized) |

E-Compression space(mm) | 600 (can be customized) |

D-Test width(mm) | 100 |

F-Beam travel distance(mm) | 772 |

H-Workbench thickness(mm) | 26 |

G-Base height(mm) | 158 |

Power supply | AC220V±10%, 50Hz/60Hz(can be customized) |

Main frame

1.Adopt single column structure, lower for tensile, upper for compression, double space. The beam is stepless lifting, light but rigid.

2.Adopting ball screw drive, realize no clearance transmission,make sure the precision control of the test force and deformation speed.

3.The photoelectric encoder is the displacement sensor, with high resolution, strong anti-interference ability.

4.The shield plate with limit mechanism used to control the beam moving range, in order to avoid sensor damaged due to the moving distance is too large.

5.The table, moving beams is made of high quality precision machining steel plate , not only reduce the vibration generated by specimen fracture, but also improve the stiffness.

5.The table, moving beams is made of high quality precision machining steel plate , not only reduce the vibration generated by specimen fracture, but also improve the stiffness.

6.The motor tail is upwards, above the work surface, this design makes the main unit lower space narrowing, the whole machine is more coordinating, and more easy to spread out the heat generated by the motor rotation, extend electrical components life.

7.Three columns of mandatory orientation, make the main unit rigidity much improved, to further ensure the repeatability of measurement.

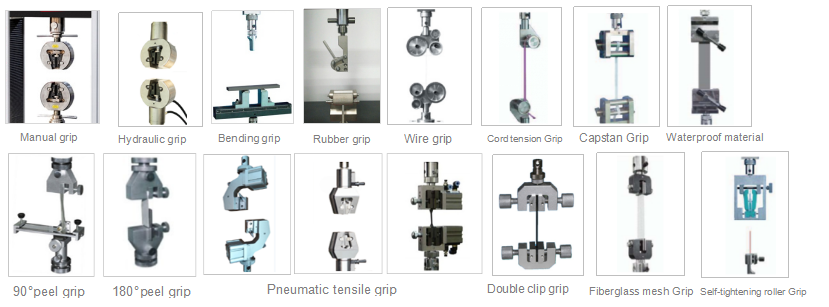

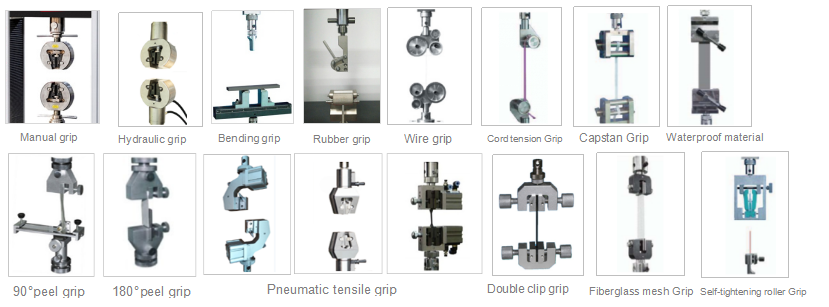

8.Adopt bolt type grip installation, make the grip replace easier.

Standard packing list:

Standard Accessories | Optional configurations |

Host | |

High strength main unit | |

Aarc synchronous deceleration system | |

ABBA High precision ball screw | |

motor | Panasonic AC Servo motor |

Compression Grip Platen Ф100mm | Other Fixture Bending Fixture |

Tensile fixture | Long travel extensometer 800mm |

Test control system | Optional |

Sensor High precision load sensor | US Celtron spoke load sensor |

HP Control PC and Printer | External touch screen display |

Controller | |

Software | |

Hand control box |

Main features of Software:

1. The test force, peak value, deformation and resolution can be calibrated automatically.

2. Curve choice:can choose Stress - strain, force - displacement, force - time, displacement - time, and other curves to display and print; Can switch at any time to observe, zoom in and zoom out, horizontal or vertical movement, real-time high speed sampling.

3. Accurate and perfect data analysis function. The mechanical performance index of test material is analyzed by man-machine interaction method.

4. provide a variety of report printing interface, users can edit any format report (such as: Excel word can achieve report printing;)

5. Keep the data interface and connect directly to the integrated information management network of the enterprise (laboratory).

6. Test standard:Integrated with about 40 kinds of national standard or test method, can meet the various test need of customers.

7. Other protection: With overload, over current, over voltage, displacement of the upper and lower limit and emergency stop protection function.

Output and print report

Excel, word, template test report, and report can be edited customize

Safety Device

1. Stroke protection: Machinery, computer double protection, prevent over preset

2. Force protection: system setting

3. Emergency stop device: handing emergencies

Application

It is applicable for wide range of material for tension, compression, bending, shearing and low cycle test. Suitable for metal, rubber, plastic, spring, textile, and components testing. It is widely used in the corresponding industries, research and development, test institutes and training centers etc.

Standards

ASTMA370,ASTME4,ASTME8,ASTME9,ISO6892,ISO7438,ISO7500-1,EN10002-4,GB/T228-2002, GB 16491-2008, HGT 3844-2008 QBT 11130-1991, GB13-22-1991, HGT 3849-2008,GB6349-1986, GB/T 1040.2-2006, ASTM C165, EN826, EN1606, EN1607, EN12430 etc.

Specification:

Model | UTM-0.1EWS, 0.2EWS, 0.3EWS, 0.5EWS, 1EWS,2EWS, 3EWS, 5EWS |

Structure | Single column double spaces |

Max. Load(kN) | 0.1 / 0.2 / 0.3 / 0.5 / 1 / 2 / 3 / 5 |

Material | All aluminum alloy surface spray painting shell |

Load accuracy | ISO 7500Class1/ Class0.5 |

Load range | 2%~100%F·S/ 0.2%~100%F·S |

Load resolution | 1/ 300000 |

Resolution of displacement | 0.01mm |

Test speed(mm/min) | 0.05-500 stepless arbitrary setting |

Speed accuracy | within ±1% set speed |

E-Tensile space(mm) | 600 (can be customized) |

E-Compression space(mm) | 600 (can be customized) |

D-Test width(mm) | 100 |

F-Beam travel distance(mm) | 772 |

H-Workbench thickness(mm) | 26 |

G-Base height(mm) | 158 |

Power supply | AC220V±10%, 50Hz/60Hz(can be customized) |

Main frame

1.Adopt single column structure, lower for tensile, upper for compression, double space. The beam is stepless lifting, light but rigid.

2.Adopting ball screw drive, realize no clearance transmission,make sure the precision control of the test force and deformation speed.

3.The photoelectric encoder is the displacement sensor, with high resolution, strong anti-interference ability.

4.The shield plate with limit mechanism used to control the beam moving range, in order to avoid sensor damaged due to the moving distance is too large.

5.The table, moving beams is made of high quality precision machining steel plate , not only reduce the vibration generated by specimen fracture, but also improve the stiffness.

5.The table, moving beams is made of high quality precision machining steel plate , not only reduce the vibration generated by specimen fracture, but also improve the stiffness.

6.The motor tail is upwards, above the work surface, this design makes the main unit lower space narrowing, the whole machine is more coordinating, and more easy to spread out the heat generated by the motor rotation, extend electrical components life.

7.Three columns of mandatory orientation, make the main unit rigidity much improved, to further ensure the repeatability of measurement.

8.Adopt bolt type grip installation, make the grip replace easier.

Standard packing list:

Standard Accessories | Optional configurations |

Host | |

High strength main unit | |

Aarc synchronous deceleration system | |

ABBA High precision ball screw | |

motor | Panasonic AC Servo motor |

Compression Grip Platen Ф100mm | Other Fixture Bending Fixture |

Tensile fixture | Long travel extensometer 800mm |

Test control system | Optional |

Sensor High precision load sensor | US Celtron spoke load sensor |

HP Control PC and Printer | External touch screen display |

Controller | |

Software | |

Hand control box |

Main features of Software:

1. The test force, peak value, deformation and resolution can be calibrated automatically.

2. Curve choice:can choose Stress - strain, force - displacement, force - time, displacement - time, and other curves to display and print; Can switch at any time to observe, zoom in and zoom out, horizontal or vertical movement, real-time high speed sampling.

3. Accurate and perfect data analysis function. The mechanical performance index of test material is analyzed by man-machine interaction method.

4. provide a variety of report printing interface, users can edit any format report (such as: Excel word can achieve report printing;)

5. Keep the data interface and connect directly to the integrated information management network of the enterprise (laboratory).

6. Test standard:Integrated with about 40 kinds of national standard or test method, can meet the various test need of customers.

7. Other protection: With overload, over current, over voltage, displacement of the upper and lower limit and emergency stop protection function.

Output and print report

Excel, word, template test report, and report can be edited customize