| Availability: | |

|---|---|

UTM-200EW

EBP INSTRUMENTS

Shanghai

90 sets / month

TT in advance

1 set

Introduction:

UTM-EW series (Dual Space) electromechanical testing machines offer force, displacement or deformation closed loop testing in tension, compression, flexure, shear, tear and peel etc.

The machine can be equipped with a variety of accessories including: grips, fixtures, compression frames, thermal cabinets and extensometers covering all relevant applications as testing of rubber, plastics, foils, films, textiles, adhesives, paper, foods, foams, timber, wires or other metallic or non-metallic specimens and medical, electronic and other components. The load frames are rigid constructed, providing superior axial and lateral stiffness.

Features:

Multi-functions:

It can perform high-capacity tension, compression, bend, flexure and shear testing which in accord with the relative requirements of ISO, ASTM, DIN, NF, EN and many other national testing methods. Interchangeable fixture design, to meet requirements of different specimen materials and test type.

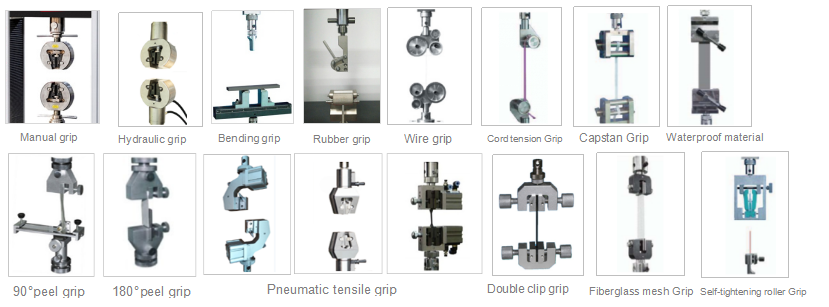

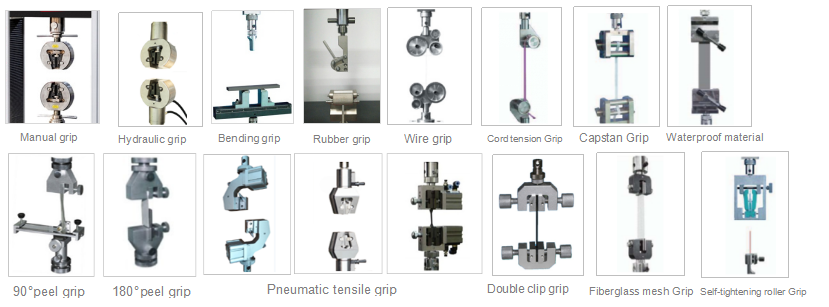

Extensive accessories:

Extensive range of accessories to meet test requirements in almost any application or industry: plastics, metals, biomedical, composites, elastomers, components, automotive, aerospace, textiles, and more.

Large test space:

Double acting crossbeam quickly accommodates specimens of varying lengths. In the case of additional length of columns, the maximum testing space is adjustable to meet extra length specimens.

High stiffness frame:

Preloaded ball screws, precision guidance columns, and a symmetrical drive system improve frame stiffness and alignment.

Over-Travel Limits:

Dual over-travel limits, located on the front console, help prevent crosshead overshooting and sensor overloads. A graduated rule along the column can be used to preset these limits to specific distances.

Safety system:

Features ensuring safety include the 2-channel (= double safeguard) safety circuit, operating-mode selector- switch, Drive Off switch and motor holding brake.

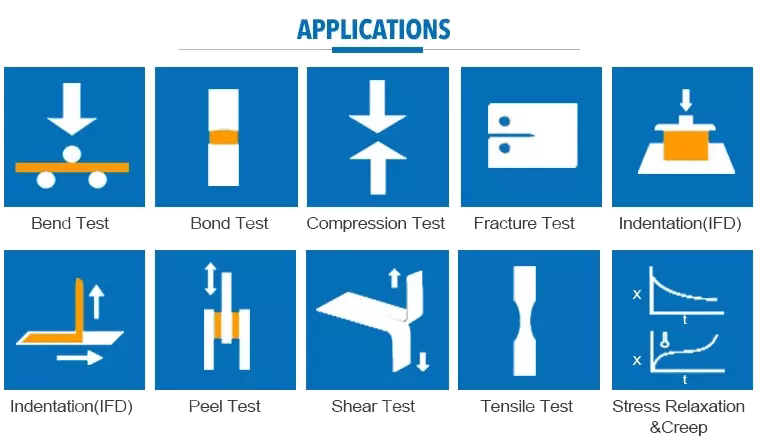

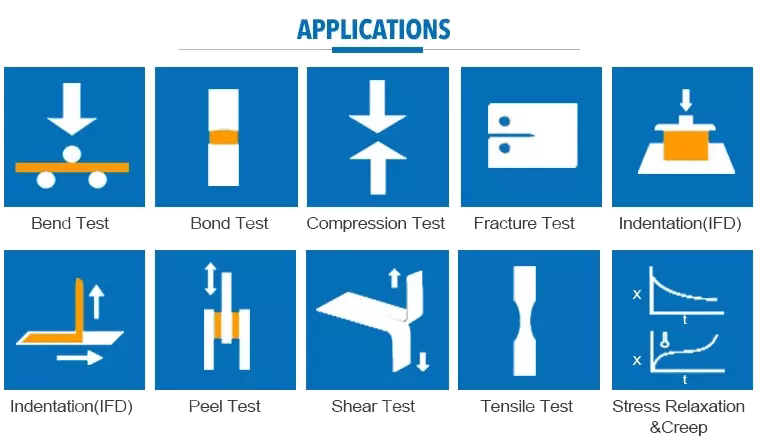

Application

Metal:

ASTM E8 Standard Test Methods for Tension Testing of Metallic Materials;

ISO 6892 Metallic materials —Tensile testing method of test at ambient temperature;

BS EN 10002-1Determination of tensile properties on metals;

ASTM E21: Standard Test Methods for Elevated Temperature Tension Tests of Metallic Materials;

IS0 783: Metallic materials -Tensile testing at elevated temperature;

EN ISO 7438 Determination of flexure tests on metals;

ISO 14589: Blind rivets - Mechanical testing;

ASTM F606: Standard Test Methods for Determining the Mechanical Properties of Externally and Internally Threaded Fasteners, Washers, Direct Tension Indicators, and Rivets

Plastics/ Composites:

ASTM D638Standard Test Method for Tensile Properties of Plastics

EN ISO 6259, EN ISO 527-1, ISO 604, ASTM D695, ASTM D3846, EN ISO 844, EN ISO 13968, EN ISO 9969, etc.

Geo-textiles:

ASTM D3950Standard Specification for Strapping, Nonmetallic; ASTM D 6775-02, BS EN ISO 10319, JBT 8521(EN 1492-2).

Rubber:

ISO 37Rubber, vulcanized or thermoplastics-determination of tensile stress-strain properties; ASTM D412, ASTM D624.

Specifications: | |||||

Model | UTM-200EW | UTM-300EW | UTM-500EW | UTM-600EW | |

Columns | Double Column | ||||

Load Capacity (kN) | 200 | 300 | 500 | 600 | |

Test Grade | 0.5 | 0.5 | 0.5 | 0.5 | |

Testing Force Accuracy | ±0.5% | ±0.5% | ±0.5% | ±0.5% | |

Testing Force Range | 0.4%-100%FS | 0.4%-100%FS | 0.4%-100%FS | 0.4%-100%FS | |

Force Resolution | 1/300000 | 1/300000 | 1/300000 | 1/300000 | |

Displacement Accuracy | ±0.5% | ±0.5% | ±0.5% | ±0.5% | |

Displacement Resolution | 0.05mm | 0.05mm | 0.05mm | 0.05mm | |

Speed Range (mm/min) | 0.01-500 | 0.01-500 | 0.01-500 | 0.01-500 | |

Control Accuracy | ±0.5% | ±0.5% | ±0.5% | ±0.5% | |

Crosshead Travel | 1100mm | 1100mm | 1100mm | 1100mm | |

Max. Tensile Testing Space(mm) | 700 | 700 | 800 | 800 | |

Max. Compression Testing Space(mm) | 1100 | 1100 | 800 | 800 | |

Test width (mm) | 600 | 600 | 700 | 700 | |

Compression Platen | Ф100mm | Ф100mm | Ф100mm | Ф100mm | |

Load cell | High-precision USA load cell offers high stiffness, high stability, and high linearity Over-load protection, lateral loading protection, Bi-direction allows tension and compression test Self-recognition (TEDS) function, Regular self-calibration | ||||

Position limit switch | Upper and lower lights | ||||

Power Supply | AC220V±10%, 50Hz/60Hz | ||||

Overall Dimensions (L*W*H: mm) | 1128*880*2414 | 1128*880*2414 | 1450*1140*2730 | 1450*1140*2730 | |

Net Weight(kG) | 2200 | 2200 4000 | 4000 | 4000 | |

Note:Extra wide and/or extra height frames are available.Power supply system is completely customizable.Tensile space, test width, and speed is completely customizable. | |||||

Introduction:

UTM-EW series (Dual Space) electromechanical testing machines offer force, displacement or deformation closed loop testing in tension, compression, flexure, shear, tear and peel etc.

The machine can be equipped with a variety of accessories including: grips, fixtures, compression frames, thermal cabinets and extensometers covering all relevant applications as testing of rubber, plastics, foils, films, textiles, adhesives, paper, foods, foams, timber, wires or other metallic or non-metallic specimens and medical, electronic and other components. The load frames are rigid constructed, providing superior axial and lateral stiffness.

Features:

Multi-functions:

It can perform high-capacity tension, compression, bend, flexure and shear testing which in accord with the relative requirements of ISO, ASTM, DIN, NF, EN and many other national testing methods. Interchangeable fixture design, to meet requirements of different specimen materials and test type.

Extensive accessories:

Extensive range of accessories to meet test requirements in almost any application or industry: plastics, metals, biomedical, composites, elastomers, components, automotive, aerospace, textiles, and more.

Large test space:

Double acting crossbeam quickly accommodates specimens of varying lengths. In the case of additional length of columns, the maximum testing space is adjustable to meet extra length specimens.

High stiffness frame:

Preloaded ball screws, precision guidance columns, and a symmetrical drive system improve frame stiffness and alignment.

Over-Travel Limits:

Dual over-travel limits, located on the front console, help prevent crosshead overshooting and sensor overloads. A graduated rule along the column can be used to preset these limits to specific distances.

Safety system:

Features ensuring safety include the 2-channel (= double safeguard) safety circuit, operating-mode selector- switch, Drive Off switch and motor holding brake.

Application

Metal:

ASTM E8 Standard Test Methods for Tension Testing of Metallic Materials;

ISO 6892 Metallic materials —Tensile testing method of test at ambient temperature;

BS EN 10002-1Determination of tensile properties on metals;

ASTM E21: Standard Test Methods for Elevated Temperature Tension Tests of Metallic Materials;

IS0 783: Metallic materials -Tensile testing at elevated temperature;

EN ISO 7438 Determination of flexure tests on metals;

ISO 14589: Blind rivets - Mechanical testing;

ASTM F606: Standard Test Methods for Determining the Mechanical Properties of Externally and Internally Threaded Fasteners, Washers, Direct Tension Indicators, and Rivets

Plastics/ Composites:

ASTM D638Standard Test Method for Tensile Properties of Plastics

EN ISO 6259, EN ISO 527-1, ISO 604, ASTM D695, ASTM D3846, EN ISO 844, EN ISO 13968, EN ISO 9969, etc.

Geo-textiles:

ASTM D3950Standard Specification for Strapping, Nonmetallic; ASTM D 6775-02, BS EN ISO 10319, JBT 8521(EN 1492-2).

Rubber:

ISO 37Rubber, vulcanized or thermoplastics-determination of tensile stress-strain properties; ASTM D412, ASTM D624.

Specifications: | |||||

Model | UTM-200EW | UTM-300EW | UTM-500EW | UTM-600EW | |

Columns | Double Column | ||||

Load Capacity (kN) | 200 | 300 | 500 | 600 | |

Test Grade | 0.5 | 0.5 | 0.5 | 0.5 | |

Testing Force Accuracy | ±0.5% | ±0.5% | ±0.5% | ±0.5% | |

Testing Force Range | 0.4%-100%FS | 0.4%-100%FS | 0.4%-100%FS | 0.4%-100%FS | |

Force Resolution | 1/300000 | 1/300000 | 1/300000 | 1/300000 | |

Displacement Accuracy | ±0.5% | ±0.5% | ±0.5% | ±0.5% | |

Displacement Resolution | 0.05mm | 0.05mm | 0.05mm | 0.05mm | |

Speed Range (mm/min) | 0.01-500 | 0.01-500 | 0.01-500 | 0.01-500 | |

Control Accuracy | ±0.5% | ±0.5% | ±0.5% | ±0.5% | |

Crosshead Travel | 1100mm | 1100mm | 1100mm | 1100mm | |

Max. Tensile Testing Space(mm) | 700 | 700 | 800 | 800 | |

Max. Compression Testing Space(mm) | 1100 | 1100 | 800 | 800 | |

Test width (mm) | 600 | 600 | 700 | 700 | |

Compression Platen | Ф100mm | Ф100mm | Ф100mm | Ф100mm | |

Load cell | High-precision USA load cell offers high stiffness, high stability, and high linearity Over-load protection, lateral loading protection, Bi-direction allows tension and compression test Self-recognition (TEDS) function, Regular self-calibration | ||||

Position limit switch | Upper and lower lights | ||||

Power Supply | AC220V±10%, 50Hz/60Hz | ||||

Overall Dimensions (L*W*H: mm) | 1128*880*2414 | 1128*880*2414 | 1450*1140*2730 | 1450*1140*2730 | |

Net Weight(kG) | 2200 | 2200 4000 | 4000 | 4000 | |

Note:Extra wide and/or extra height frames are available.Power supply system is completely customizable.Tensile space, test width, and speed is completely customizable. | |||||